The PAT4Nano consortium has been operating virtually since the project began due to COVID restrictions, however, this month we finally had our first face to face meeting in the Netherlands. On the 25 and 26th of April 2022 we held a series of two meetings to showcase some of the latest particle size analysis technologies being developed by the consortium.

On Monday we were hosted by TNO at the Brightlands Materials Centre, on the Chemelot campus (www.brightlandsmaterialscenter.com/ ) in Geleen. The meeting comprised of a review of the different measurement technologies being developed as part of workpackage 2 and validation trials as part of workpackage 3, followed by a tour of the facilities and a demonstration of the online Laser Diffraction solution being developed as part of the project. This enables Laser Diffraction measurements to be made from concentrated nanosuspensions. This is a collaboration between TNO and MalvernPananalytical/

Caption: Some of the PAT4Nano consortium members getting ready for the technical session on Monday morning.

Caption: Getting an overview of the Sustainable Buildings and Industry technologies being developed at the Brightlands materials centre from Roberto Habets. Many of the materials (like energy efficient windows or photocatalysts for sunlight fueled chemistry) being developed require the use of nanoparticles and nanosuspensions, hence the involvement with PAT4Nano. The manufacture of these energy efficient materials and coatings requires nanoparticle sizes to be strictly controlled during manufacture.

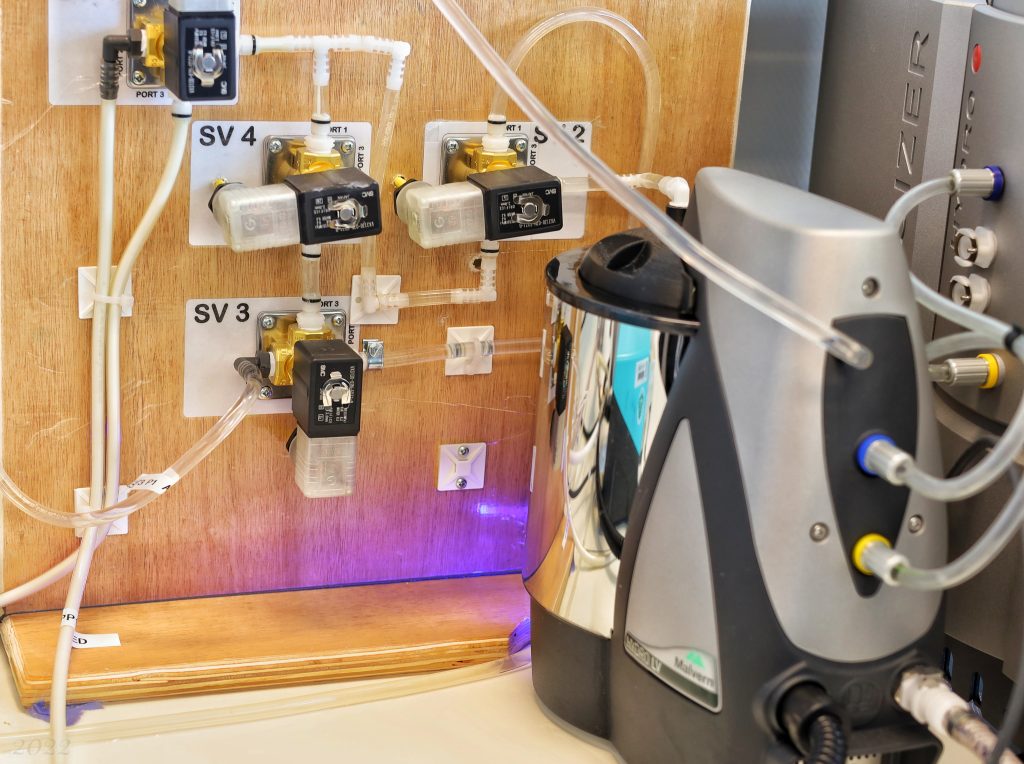

Caption: This shows the prototype sampling loop connected to a Mastersizer Laser Diffraction system. The loop is connected to a nano-mill (Buhler PML-2 bead mill system with Centex S2 milling chamber).

Caption: Luc Leufkens of TNO explaining the nano-milling process being demonstrated in the fumecupboard.

TUESDAY:

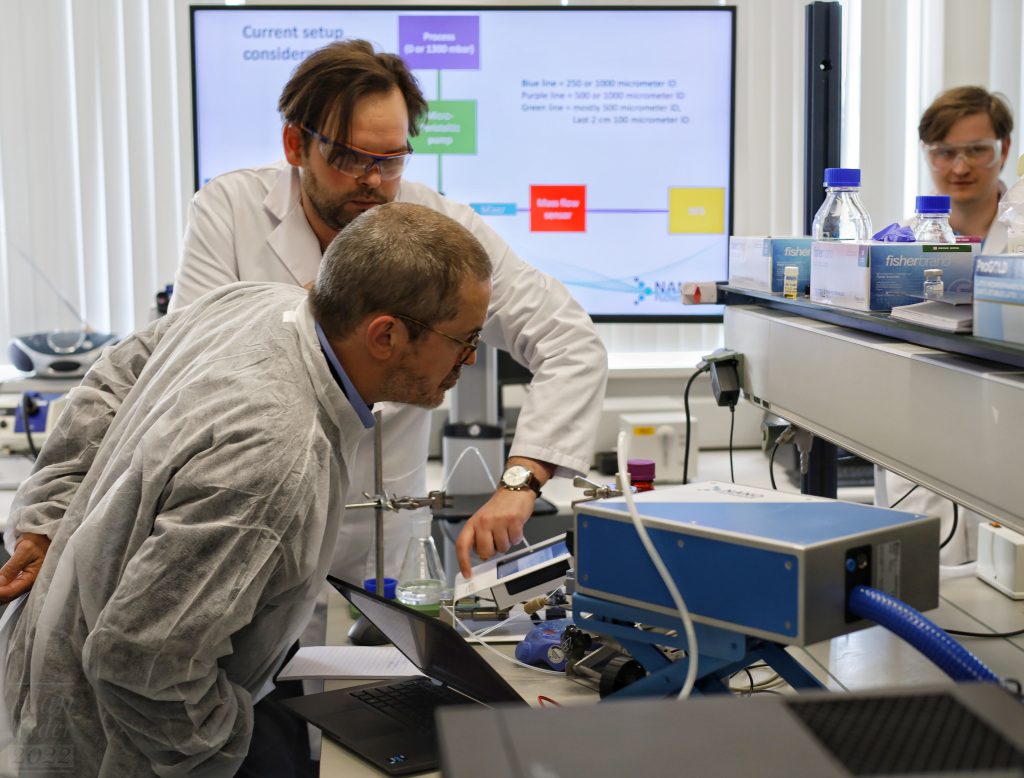

On Tuesday the consortium was hosted by InProcess-LSP in Oss, on the Pivot Park campus. During this visit InProcess demonstrated their Nanoflowsizer in operation, following a High Pressure Homogenization (HPH) process in real time using an online flow cell. An active feedback loop was integrated in the NanoFlowSizer software to control the High Pressure Homogenizer of GEA. The particle size, size distribution and polydispersity index was obtained every 10 seconds during the process and used as feedback to the HPH system by adjusting the process settings such as pressure to tune the process to the target particle (in this case 200 nm). This was a good example how real time measurements are used for direct feedback to fully control the process in an automated manner. Thanks to the InProcess-LSP team members Remy van Tuijn (Process Engineer) and Marko Verbeek (Senior Software Programmer) for showcasing this useful feature.

Caption: Some of the PAT4Nano consortium members being briefed on the Nanoflowsizer in operation.

Caption: Guarding the Nanoflowsizer: Remy van Tuijn as one of the main developers of the HPH process integration from InProcess-LSP is making sure everything is standby to start the homogenization run. Marko Verbeek as senior software programmer is ready in the back to explain the Pat4Nano crowd how the XsperGo software (operational software for the NanoFlowSizer) shows the particle size results in real time and how it controls the HPH system.

Caption: The picture shows the NFS coupled to GEA High Pressure Homogenization system. The sampling interface is a flow cell which is located in the middle of the image, it being attached directly to the NFS via a demountable sampling plate (showing a white / milky highly turbid suspension).

Caption: They also showcased their new GMP compliant software and a novel sampling system for online particle size measurements of concentrated solutions. Here we see Carl Schuurmans (Senior Scientist of InProcess-LSP) demonstrate some of the finer points of the system to Bart Wuytens from Agfa Gevaert, another company member in PAT4Nano.